BMW Fuel Injector Replacement

Very recently, a customer of our’s brought in his 2008 BMW 335i (“E90″/”E9X”) for diagnosis and repair, reporting a “hesitation under acceleration” and a “rough idle”, as well as the following Diagnostic Trouble Codes, or DTC’s present in the on-board computer:

- 29D0 – Cylinder #4 Misfire

- 2AAF – Relating to signal interruption from high-pressure fuel pump

- 2A2D – Relating to low pressure fuel pump

- 2909 – Relating to fuel system malfunction

Being a “direct-injected” engine with over 65,000 miles on the clock, we initially suspected carbon build-up in the intake ports to be the culprit, as that’s a common problem with all direct fuel-injection engines of this configuration.

See our earlier post about Carbon Build-up here.

After removing the intake manifold and exposing the intake ports, we could see that carbon had indeed accumulated enough to easily disrupt the smooth operation of the engine. Before going further, that carbon had to be cleaned off using a process called walnut-shell abrasive blasting. Once that was finished, the engine did run quite a lot better but we could tell that the carbon wasn’t the only underlying issue. The check engine light (“CEL”) returned and we suspected there might be some problems with the fuel injectors themselves so, we put the car back on a lift to dive in a little deeper, and this is what we found…

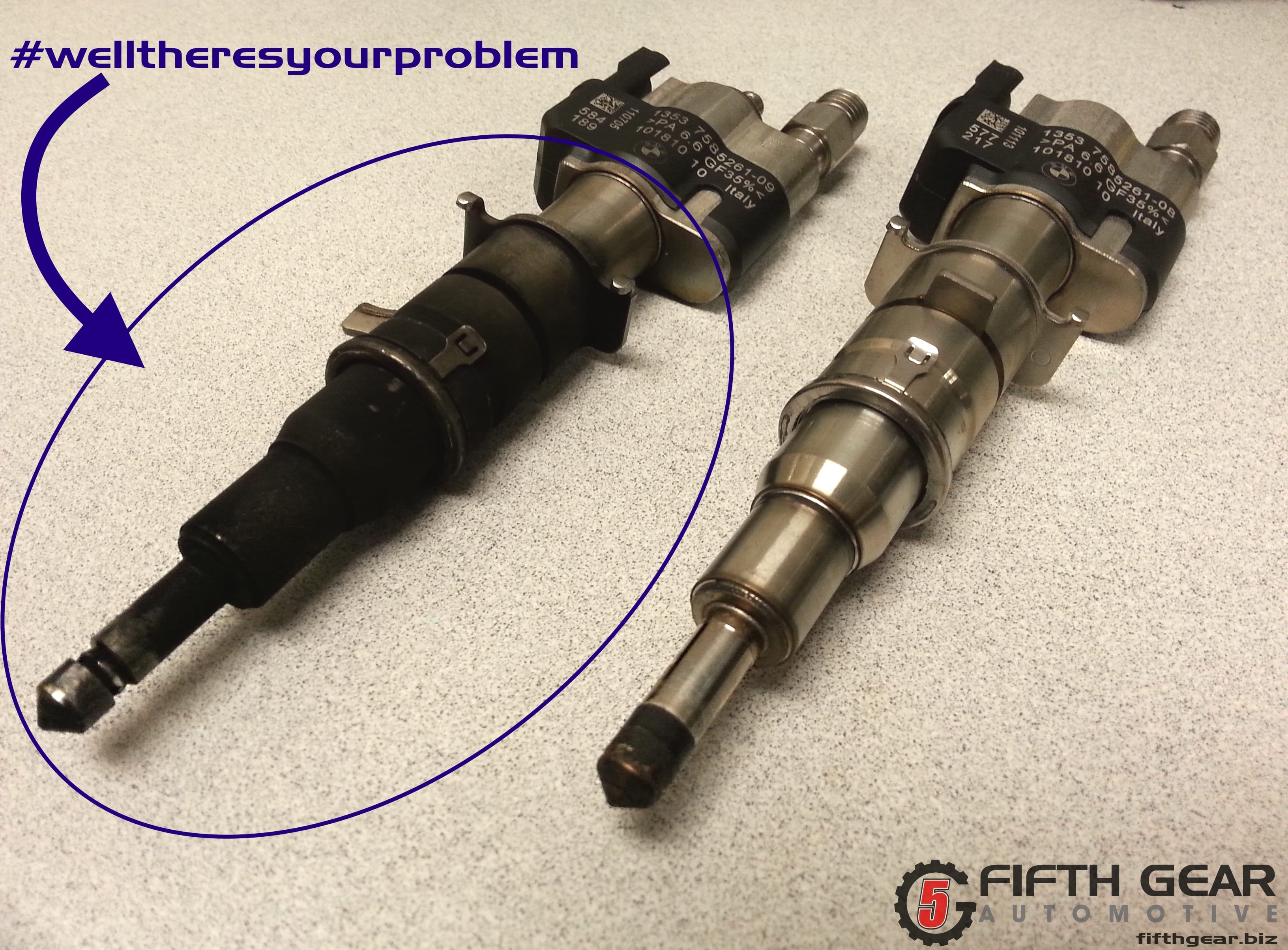

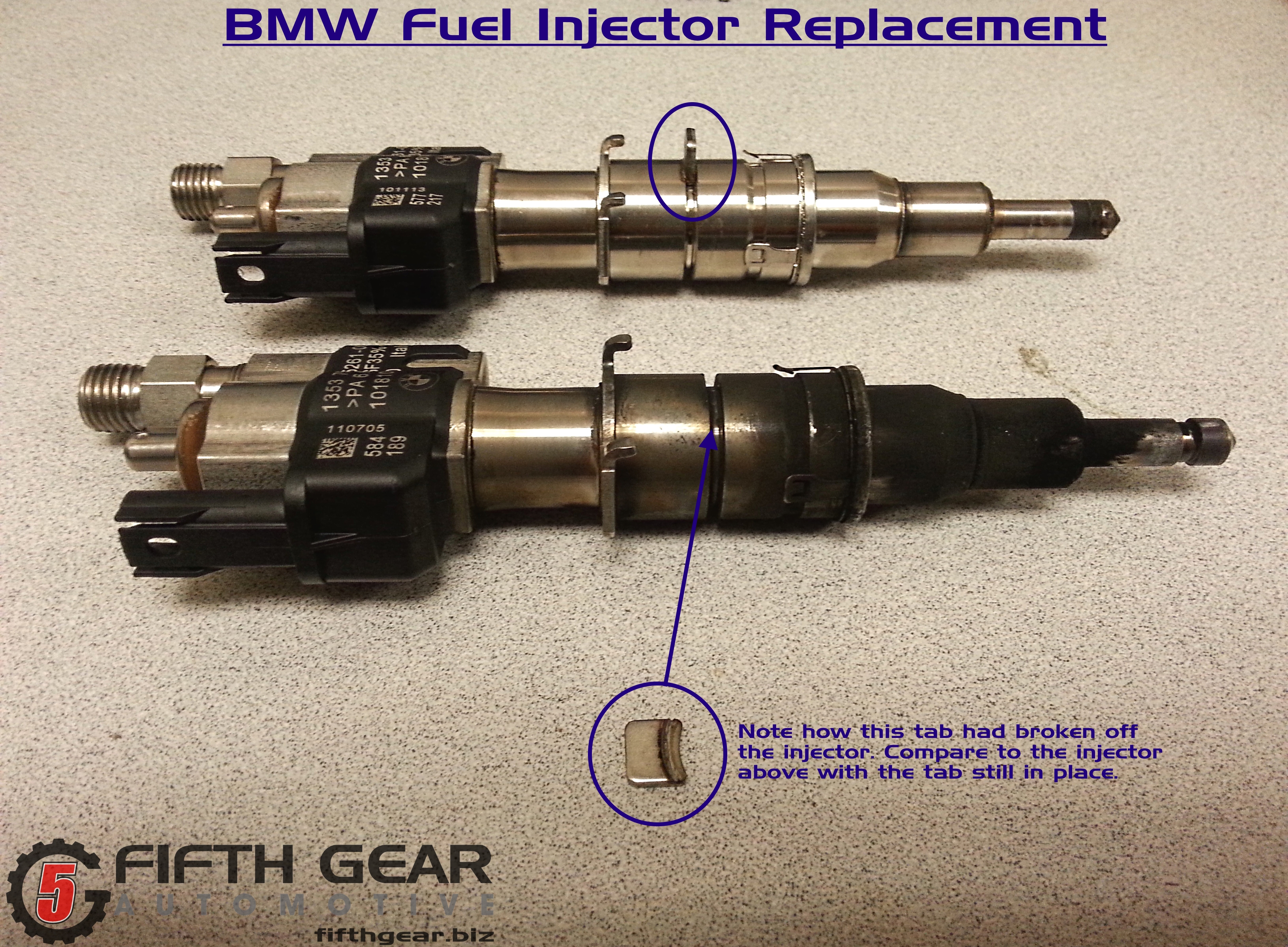

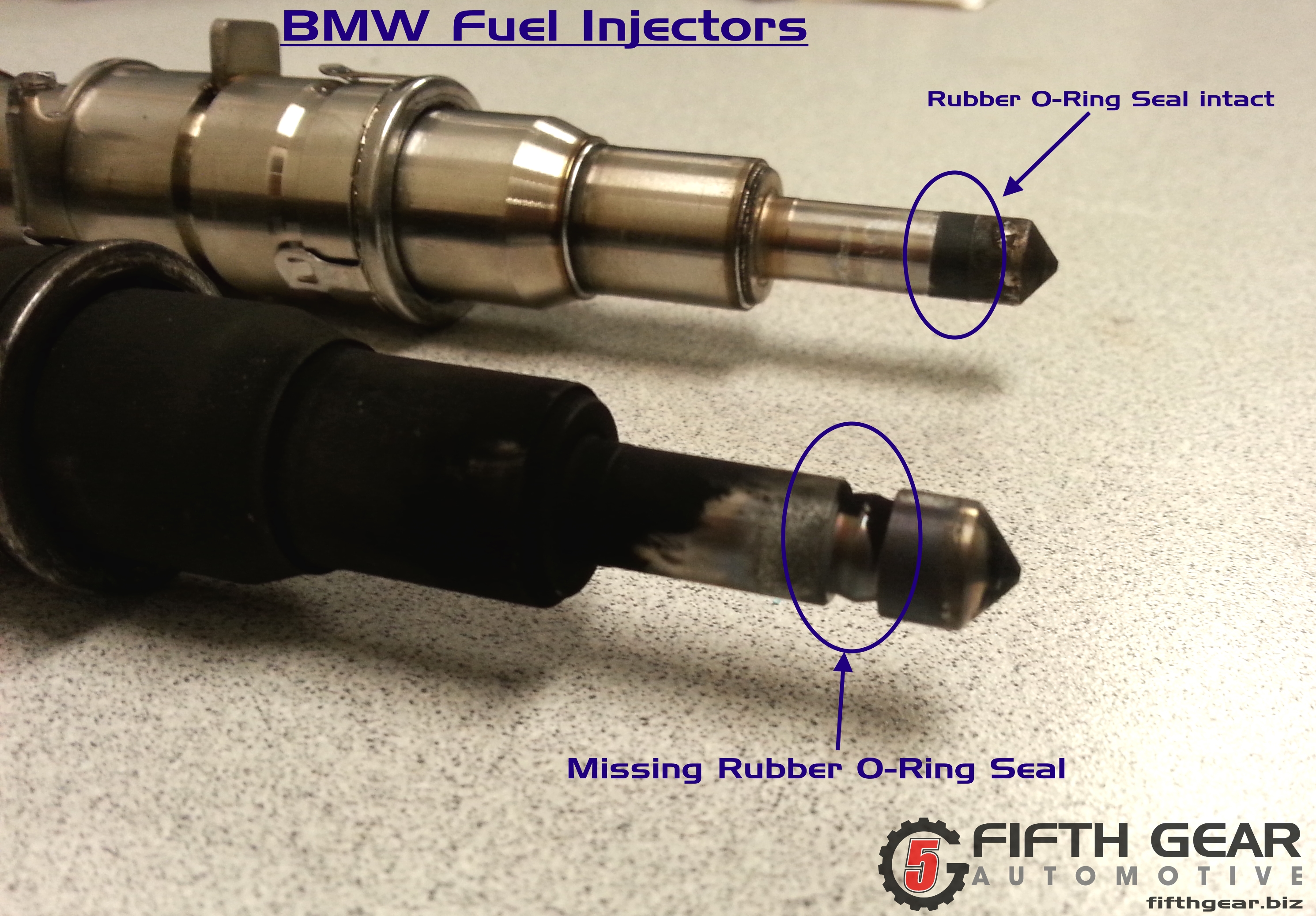

As you can see in the images below of two of the fuel injectors we removed from this car, there are a few things going on here:

1. One of the mounting tabs the holds the injectors firmly in place had broken off, allowing the force of combustion to push the injector up of place during each combustion stroke.

2. This allowed combustion gasses and pressure to escape through the gap once occupied by the tip of the injector, the evidence of which can be clearly seen in the form of that black charring covering the face of the injector in question.

3. The slight gap where the combustion was escaping was exacerbated when the thick o-ring on the tip of the injector was exposed to the heat of combustion and burned away.

(Click for larger images)

Clearly the injector needed to be replaced, but many people may not realize that due to the way these injectors are coded and controlled by the on-board engine management software, you have to replace all the injectors in the bank from which the failed part is removed (in this case, Bank 2). So, after removing injectors 4, 5, and 6 we replaced them with all new OEM BMW parts, coded them to the vehicle’s DME using our sophisticated BMW scan-tool, and took the car out for a drive to determine if the problems were well and truly fixed. Our customer was pleased as punch when he picked up his Bimmer, telling us that it ran better than it had in a long time. All in a day’s work!